Roll Changing Arrangement In 4hi Mills

.jpg)

Advanced Cold Rolling Mills Tenova

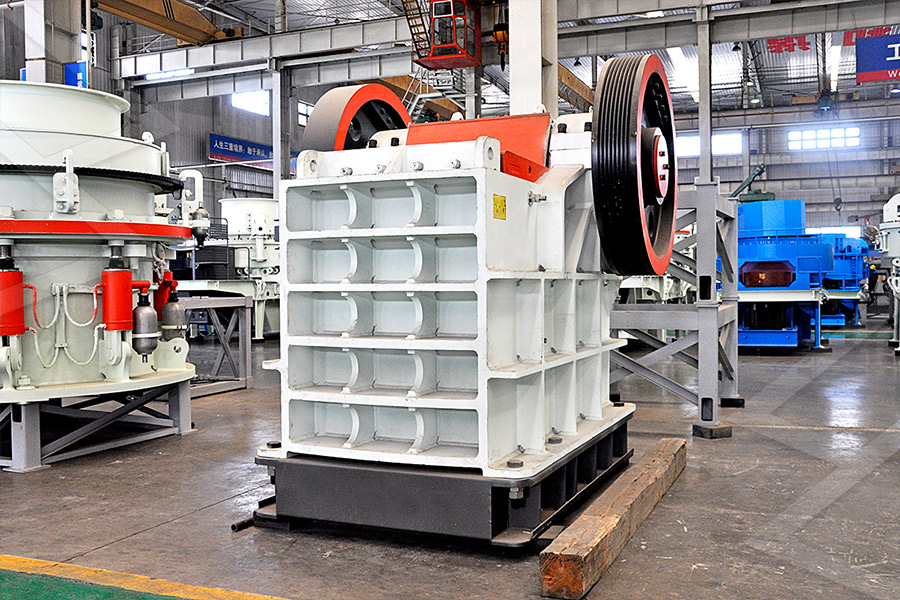

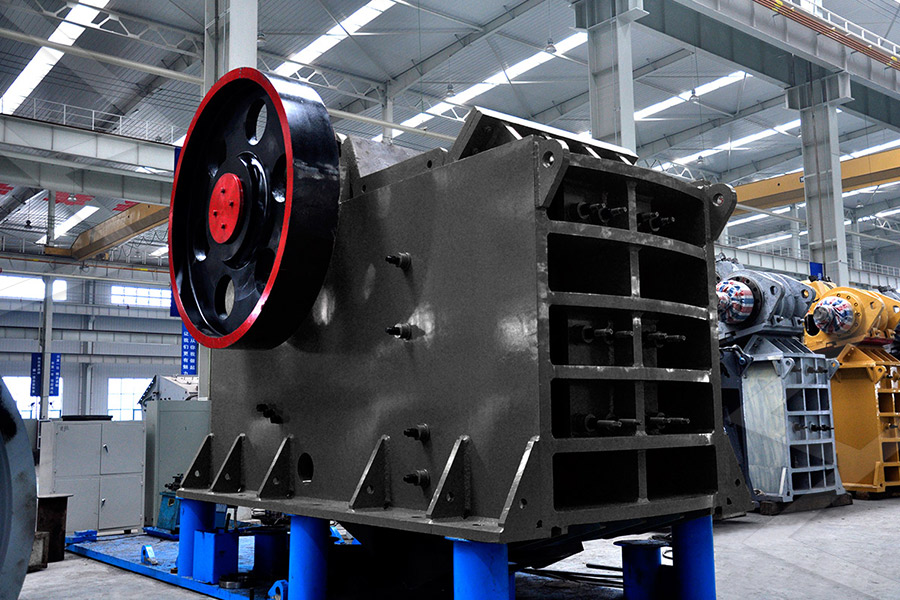

2023年3月9日 Tenova I2S employs an analytical rolling mill design method to ensure an optimum mill solution for the specific customer product mix Tenova I2S offers expertise, Quick RollChanging Systems High performance closed loop automatic thickness and flatness control systems Optional features can be applied depending on application Work roll sets with different roll diameters Special roll gap 4hi Mills DANIELI Germany2021年8月5日 The 4th generation PC Mill developed as the next flagship hot rolling mill has fewer parts requiring maintenance due to its full hydraulic cylinder control and is capable of 4th Generation PC Mill Promoting DX (Digital A four roll configuration is known as a 4 High Rolling Mill, whereby the work rolls are generally smaller in diameter supported by larger backup rollers These mill can be used for tighter tolerance output material, and for reducing material to 4 HIGH ROLLING MILL Element Machinery

Sundwig 4high cold rolling mill Andritz

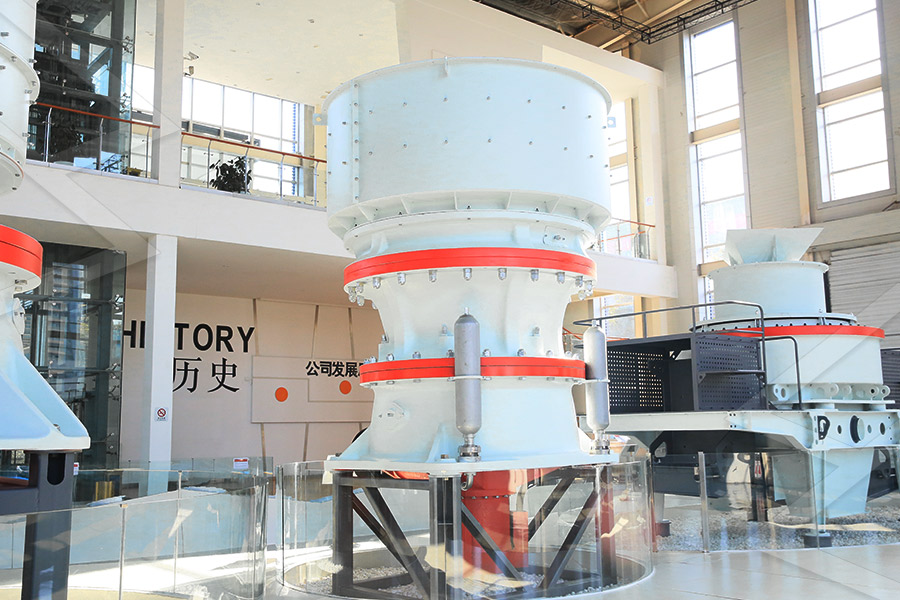

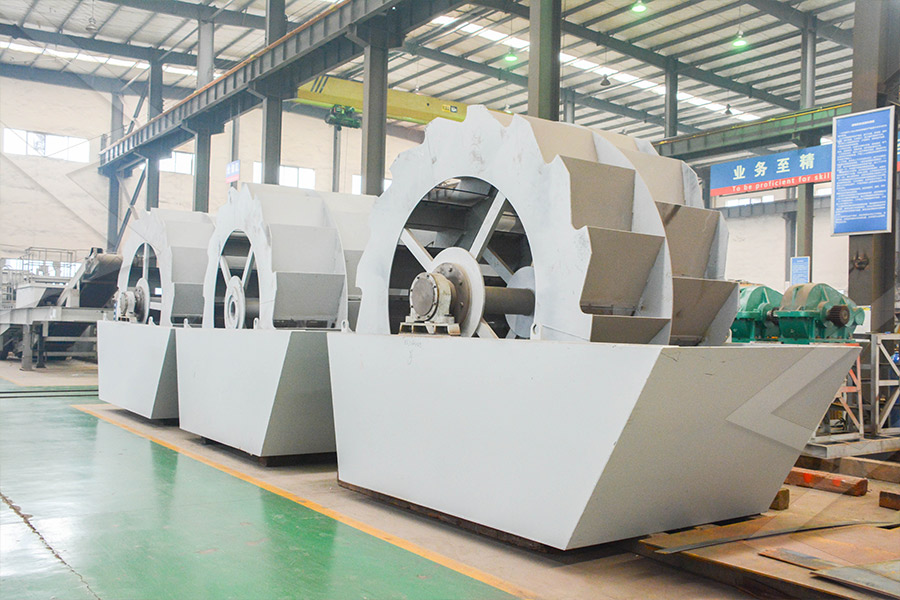

Strengths and benefits of the 4high cold rolling mill Rolling technology for highest quality standards Proven and sophisticated design, with more than 50 references worldwide Meets the most exacting requirements regarding 2011年7月1日 For gaining strip edge drop controllability and increasing roll grinding precision, the edge drop control work roll (EDW) was developed and designed in 1700 mm tandem cold Edge Drop Control Technology of 4Hi Tandem Cold Rolling Mill 2023年3月9日 Hydraulic/Electrical motors/cylinder drives the changer wheels when moving it to and from the Mill A single hydraulic cylinder indexes the side shifting table horizontally Cold Rolling Mill TenovaYour benefits Automatic roll changing system: work rolls and intermediate rolls can be changed automatically Quick and large roll gap opening: strip feeding can be executed easily and METALS SUNDWIG FOUR COLUMN 20HIGH ROLLING

.jpg)

Application of Machine Learning to Tandem Cold Mill

2021年4月22日 211 Setting of reduction and tension First, the rolling reduction and tension between stands are set on the basis of the given manufacturing conditions (eg product 2023年3月9日 Mill Speed: 1250 m/min Mill Stand Features: Hydraulic Screwdown, Roll BendingMae West, Roll Changer, PassLine Wedge Adjustment, Spindle Supports, Side Guides Pressure Board, USC Zone Controlled Coolant Sprays, Doctor Knife, Backup Roll Wipers, Upper Work Roll Air Wipers Cold Reversing Mill 3Cold Rolling Mill TenovaDouble Outboard gear arrangement allows for fine roll adjustment; Screw down design has a manual single wheel for rapid roll change between passes; Reduction gearing supports on roller bearings throughout; Our sheet and Rolling Mills N Ferrara Inc The Leader in 2002年11月30日 Lechler offers a wide range of nozzles and nozzle systems for optimum roll cooling in hot and cold rolling mills India; Choose a language: Deutschland; Germany; The fundamentals for efficient and economical roll Roll Cooling Lechler

.jpg)

Essential mechanical properties of work roll for effective

2020年11月2日 This imperative study will be helpful for rolling mill engineers and operators for selection of measure operating parameters for adequate rolling which must have higher efficiency and life of work roll The work also includes the study the current material used for manufacturing work roll for rolling mills2021年4月22日 On the other hand, Hitchcock’s roll flattening theFig 1 Tandem cold mill setup flow chart ory assumes that the shape of the roll surface remains Application of Machine Learning to Tandem Cold Mill Setup JFE TECHNICAL REPORT No 26 (Mar 2021) 53 circular even after roll elastic deformation and theApplication of Machine Learning to Tandem Cold Mill 2024年8月10日 #1 Two High Rolling Mills It contains two heavy rolls fixed one over the other The rolls are supported in bearings housed in sturdy upright frames (called stands) which are grouted to the rolling mill floor The vertical gap between the roll is adjustable The rolls rotate in opposite directions and are driven by electrical motorsRolling Mills: 6 Different Types of Rolling Mills [Images PDF]Our specially developed technology and advanced control elements, for fine adjustment of the roll gap through hydraulic AGC system combined with variable roll bending (VRB) and zonal coolant, roll shifting increase the productivity and the product quality 6Hi/4Hi/2Hi cold rolling mills Width 300mm1250mm and more Thickness from 010 RollCon EnggCo

4High Rolling Mills Metal Processing Machinery American Steel

2024年7月31日 This is becoming common whether a 2high, 4high, 6high, or cluster mill Before dual motor drives, rolls had to be ground the same diameter If one roll needs to be ground, the opposing roll must be ground at the same diameter Fourhigh mills are very common for steel, aluminum, copper, and any high production metal rolling2013年1月4日 8 Rolls are small in diameter hence smaller grinder is required for regrinding 20 Hi Mills are unique in feature as they have chockless floating work rolls and a cluster configuration for the backup bearings Configuration of 20 Hi Mill Rolls is given below BSI 1 = Work Roll 2 = Intermediate Roll D = Drive Roll I = Idler Roll 4 = Back Up 20 Hi Mill Rolls deeteegroup2013年11月22日 Slitting sizing of CR strip 10 Packing 1 Raw Material slitting A Cold Rolling Mill, is typically a Sendzimer type mill and is PLC controlled CRM’s may be 4 Hi Reversible Mill or 8 Hi reversible A 4 Hi mill, consists of two work rolls and two back up rolls and rolling operations can be reversed, hence the nomenclatureCold rolling on a 4 hi reversible mill PDF SlideShare2023年5月9日 CONDITIONS OF 4HI ROLLING MILL AIMING GUARANTEE OF ITS OPERATIONAL STABILITY1* Gustavo de Sousa2 Rodney Pardo Alves3 Emanuelle Garcia Reis4 Bending and Work Roll Shiftting arrangement with Smart Crown® * Technical contribution to the 11th International Rolling Conference, part of the ABM Week 2019, October 1st3rd, 2019, TECHNIQUES FOR EVALUATING THE MECHANICAL

4 Hi skin pass mills (SPM) GLIMPSE

Highspeed roll changing Stable rolling 2HI skin pass mill Designed to provide the high degree of cleanliness required for 2 Hi 4HI skin pass mill Designed for a variety of steel grades from very low to very high strength; Used on 2021年8月5日 The 4Hi mill shown in Figure 1 has many applications in hot rolling mills and the PC Mill has the same 4Hi mill structure As you can see in Figure 1, when the strip is rolled, the work roll is deformed by the rolling load, which creates a strip crown Rolling out a hard material causes a high rolling load, which generates a large strip crown4th Generation PC Mill Promoting DX (Digital Intermediate Finishing Mills The versatile Waterbury Farrel 4Hi Mill can be deployed as both a nonreversing mill for intermediate rolling and as a reversing mill for finish rolling Smaller work rolls allow for more efficient material reduction The larger backup roll positioned against the smaller work roll reduces separating forces and Waterbury FarrelThe 4Hi Cold Rolling Mills are used for rolling of coils, sheets and plates of all types of metals and alloys like Stainless Steel, Mild Steel, Brass, Copper, CuproNickel, Aluminum etc We have manufactured more than 400 such rolling mills running successfully all over India and abroad in countries like Brazil, Turkey, Malaysia, Nigeria, Kenya cold rolling mills, 2 hi cold rolling mill, 4 hi cold rolling mill

Hot Rolling Mills Manufacturer in Delhi

This mill can take in an input thickness of 100 mm We offer rolling mill equipments for ferrous and nonferrous products It has two Backup Rolls that are made of Adamite/ EN31 forged alloy steel and the three Work Rolls are made of EN9/EN31 forged alloy steel This Hot Rolling Mill is used in rolling out sheets of optimum quality steelFor gaining strip edge drop controllability and increasing roll grinding precision, the edge drop control work roll (EDW) was developed and designed in 1700 mm tandem cold rolling mill During the rolling trial, the roll configuration between EDW and conventional backup roll didn’t match well because of the large fluctuation of strip edge drop, the lower shape control ability and non Edge Drop Control Technology of 4Hi Tandem Cold Rolling Mill A special design feature is the patented Double Bending Technology, applying roll bending to the inner and outer intermediate rolls The number of flatness control elements is unique in a DANIELI FRÖHLING 20High Mill with roll stack tilting, backup roller bearing shaft crown adjustment, bending of outer intermediate rolls, bending of inner intermediate rolls, and lateral shifting of 1220hi mills DANIELI GermanyVarious parts of the mill like the Rolls, Housings, Gear Box, Screw Down and drive system are matched properly to give optimum performance with minimal down time in maintenance and repairs In reversing cold mills the tension reels are placed on both ends of a single or twomillstand arrangementCold Rolling Mills ctlline

Cold Rolling Mill Automation System Detailed Case Study

The mill rolls a wide variety of products, including 3XXX, 5XXX, and 6XXX aluminum alloys at exit gauges down to 00055 inch This means that bumpless transition mechanisms are provided for changing between modes while rolling The ITC system consists of separate control modes for initial mill threading and steadystate rolling The The ability to track and analyze deviations in the performance of CRMs with ABB Ability™ Data Analytics for cold rolling mills is an important step in equipping CRM operators for the challenging market conditions they face, and is the Improving cold rolling mill performance with 2015年5月18日 2 Basics of Rolling A rolling mill consist of several, at least two rolls cylindrical or nearly cylindrical bodies which are termed as “roll” and which rest in bearings at their ends The normal and average center distance from Roll pass design in continuous bar mills PPT2013年11月11日 work roll for the former is desirable to be smaller and the diameter of a work roll for the latter is desirable to be larger for a stable operation, so the installation of a 4Hi dual diameter roll skinpass mill equipped with 2 kinds of work roll diameter is increasing Likewise, in regard to the polishing method used for work rolls, a nylonRecent Development of Skinpass Mill and Tension Leveler

.jpg)

Backup Rollers for multiroll cold rolling mills

2020年11月26日 Multiroll cold mill stands are described using different terms depending on their type and manufacturer: 12 and 20 roll stand ZHigh® SHigh Multiroll cold rolling mills are used to process high grade steel strip and nonferrous metal strip In order to prevent whipping of the work rolls, they are supported by means of intermediateThe Sundwig 4high mill is equipped with positive and negative work roll bending in order to influence the shape and the flatness of the strip Either the work roll or the backup roll is driven, depending on customer requirements The diameter of the 4high work rolls amounts to approximately 1:4 in relation to the barrel lengthSundwig 4high cold rolling mill Andritz2022年12月20日 3 Towershaped roll system, multipivot beam support roll structure, large rolling mill steel, small roll warping deformation, good shape, and high precision of rolled products 4 The rolling mill is small in size and light in weight, and the mass of the rolling mill is about half of that of other types of rolling mills of the same Characteristics and application of 20 hi cold rolling millChina 4hi 6hi Rolling Mill wholesale Select 2024 high quality 4hi 6hi Rolling Mill products in best price from certified Chinese Automatic Rolling Machine manufacturers, Rice Mill Machine suppliers, wholesalers and factory on MadeinChina 2hi 4hi 6hi 8hi Rolling Mill Stand in Tandem Arrangement for Hot Rolled Steel US$ 13501600 China 4hi 6hi Rolling Mill, 4hi 6hi Rolling Mill Wholesale

.jpg)

Review on cold rolling mill roll deformation IJOER

2024年9月7日 Hi or 6 Hi rolling mill (4 to 10 microns) The arrangement of the rolls in the rolling mill decides the speed and the maximum reduction in the rolling mill The rolling mills which are having more number of rolls will give more reduction in the sheet The complex arrangement in4Hi Cold Rolling Mill Supplier, 6Hi Cold Rolling Mill, 8Hi Cold Rolling Mill Manufacturers/ Suppliers Hebei Moran Environmental Protection Technology Corp Push Pull Pickling Line Slitting Line for Cold Roll Mill FOB Price: US $700,0002,000,000 / Set Min Order: Roll Changing Car/Accessories for Cold Rolling Mill Machine FOB Price 4Hi Cold Rolling Mill Manufacturer, 6Hi Cold Rolling Mill, 8Hi 4 天之前 Our rolling mills are available in 2Hi and 4Hi roll configurations Mills may be either work rolldriven, backup rolldriven, or a combination of both 4HI mills with work rolls are offered as small as 500″ (127mm) in diameter; 2HI mills are Rolling Mills Metal Rolling Mill Machine Rolling Mill 2023年3月9日 Mill Speed: 1250 m/min Mill Stand Features: Hydraulic Screwdown, Roll BendingMae West, Roll Changer, PassLine Wedge Adjustment, Spindle Supports, Side Guides Pressure Board, USC Zone Controlled Coolant Sprays, Doctor Knife, Backup Roll Wipers, Upper Work Roll Air Wipers Cold Reversing Mill 3Cold Rolling Mill Tenova

.jpg)

Rolling Mills N Ferrara Inc The Leader in

Double Outboard gear arrangement allows for fine roll adjustment; Screw down design has a manual single wheel for rapid roll change between passes; Reduction gearing supports on roller bearings throughout; Our sheet and 2002年11月30日 Lechler offers a wide range of nozzles and nozzle systems for optimum roll cooling in hot and cold rolling mills India; Choose a language: Deutschland; Germany; The fundamentals for efficient and economical roll Roll Cooling Lechler2020年11月2日 This imperative study will be helpful for rolling mill engineers and operators for selection of measure operating parameters for adequate rolling which must have higher efficiency and life of work roll The work also includes the study the current material used for manufacturing work roll for rolling millsEssential mechanical properties of work roll for effective 2021年4月22日 On the other hand, Hitchcock’s roll flattening theFig 1 Tandem cold mill setup flow chart ory assumes that the shape of the roll surface remains Application of Machine Learning to Tandem Cold Mill Setup JFE TECHNICAL REPORT No 26 (Mar 2021) 53 circular even after roll elastic deformation and theApplication of Machine Learning to Tandem Cold Mill

Rolling Mills: 6 Different Types of Rolling Mills [Images PDF]

2024年8月10日 #1 Two High Rolling Mills It contains two heavy rolls fixed one over the other The rolls are supported in bearings housed in sturdy upright frames (called stands) which are grouted to the rolling mill floor The vertical gap between the roll is adjustable The rolls rotate in opposite directions and are driven by electrical motorsOur specially developed technology and advanced control elements, for fine adjustment of the roll gap through hydraulic AGC system combined with variable roll bending (VRB) and zonal coolant, roll shifting increase the productivity and the product quality 6Hi/4Hi/2Hi cold rolling mills Width 300mm1250mm and more Thickness from 010 RollCon EnggCo2024年7月31日 This is becoming common whether a 2high, 4high, 6high, or cluster mill Before dual motor drives, rolls had to be ground the same diameter If one roll needs to be ground, the opposing roll must be ground at the same diameter Fourhigh mills are very common for steel, aluminum, copper, and any high production metal rolling4High Rolling Mills Metal Processing Machinery American Steel2013年1月4日 8 Rolls are small in diameter hence smaller grinder is required for regrinding 20 Hi Mills are unique in feature as they have chockless floating work rolls and a cluster configuration for the backup bearings Configuration of 20 Hi Mill Rolls is given below BSI 1 = Work Roll 2 = Intermediate Roll D = Drive Roll I = Idler Roll 4 = Back Up 20 Hi Mill Rolls deeteegroup

.jpg)

Cold rolling on a 4 hi reversible mill PDF SlideShare

2013年11月22日 Slitting sizing of CR strip 10 Packing 1 Raw Material slitting A Cold Rolling Mill, is typically a Sendzimer type mill and is PLC controlled CRM’s may be 4 Hi Reversible Mill or 8 Hi reversible A 4 Hi mill, consists of two work rolls and two back up rolls and rolling operations can be reversed, hence the nomenclature