Crusher Distributor Impact Factor

Experimental Study of the Crushing Characteristics of Single

1 天前 The crushing process of material particles in a vertical shaft impact (VSI) crusher is highly complex It is hard to quantify and characterize the crushing behavior of particles In this work, 2002年10月1日 PDF In this paper we develop a performance model for impact crushers The product size distribution is obtained as a function of the crusher’s rotor Find, read and cite all the(PDF) A performance model for impact crushers2024年7月11日 A rotary impact testing apparatus is devised in this article in adherence to the vertical shaft impact crusher’s crushing principle The primary operational components of the The Crushing Distribution Morphology of a Single Particle 2024年7月26日 HSI crushers have one main method of crushing, that of impact This impact comes primarily from a high speed rotating rotor, mounted horizontally in the crusher and fitted HSI Crushers 911 Metallurgist

IMPACT CRUSHERS HAZEMAG

Learn more about our Impact Crushers HAZEMAG can supply the most suitable impactor for practically every primary crushing application Our single and doublerotor impactors process 2021年3月20日 A number of experiments were conducted on a laboratory batch impact crusher to investigate the effects of particle size and impeller speed on grinding rate and product size distribution The experiments involved feeding a Milling Studies in an Impact Crusher I: Kinetics 2022年11月21日 Impact crushers The ideal crushers for mediumhard to hard material Our solutions for the hardest jobs reliability and costeffectiveness With us as your partner, you Industrial Solutions Impact crushers ThyssenKrupp2022年6月27日 PROCESS BENEFITS HIGH CAPACITY Large unobstructed feed opening, heavyduty breaker plates and heavy rotor are designed to accept big feed size for high MEKA CRUSHING SCREENING AND CONCRETE

.jpg)

Collision Energy Analysis within the Vertical

2024年2月7日 Particles in the vertical shaft impact crusher absorb and dissipate collision energy in the impact breakage The distribution of the collision energy determines the breakage rate of materials and breakage energy consumption HAZEMAG impact crushers can handle individual lumps of feed material up to 8 tons in weight and 3 m3 (100 cuft) in volume, effecting the comminution process in a single pass at capacities of over 2200 tons/hour Even feed material with a high moisture content up to 15% H2O can be processed without any problems by the provision of indirect IMPACT CRUSHERS HAZEMAG2014年2月1日 A dynamic cone crusher model that describes the output size distribution (size reduction), and the flow was presented in this work Simulations have showed that the steadystate model behavior is qualitatively consistent with measured crusher behavior, as reported in eg ( Lee and Evertsson, 2011 ), in terms of response to changing the Control oriented modeling of flow and size distribution in The impact crusher range from Powerscreen is ideal for shaping applications, making chips, sand, concrete manufacture, and glass recycling Trakpactor 260SR features a postscreen system and recirculating conveyor that can Impact Crusher Powerscreen Impact Crushers

.jpg)

Understanding the impact of geotechnical ore properties and blast

2021年8月15日 Higher powder factor also decreases the SSE of the whole circuit The rock fragmentation parameter, Rock Quality Designation (RQD), mainly impacts the coarser end of ROM size distribution; as the primary crusher breaks those coarser particles, no significant RQD effect on the plant throughput and the Size Specific Energy was observed2024年4月19日 Impact Crusher: Uses highspeed rotors with attached hammers or blow bars to strike and break material product and the possibility of other screening or classification equipment are largely dependent on the particle size distribution that is required The capital cost of crusher is the most important factor to consider before the Types of Crushers Explained: Everything You Need to Know2021年12月3日 The present study investigates the effects of rock crushing circuits on aggregate quality For this purpose, a crushingscreening plant located in Vize (Kırklareli, Turkey) was considered(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY The fine impact crusher SMR/CI is mainly used to produce sand which is an excellent additional material for the production of concrete and asphalt This crusher shows a sturdy construction and can easily be adjusted to varying operation conditions thanks to using different rotors Wear is reduced due to the special impact chamber geometry and SBM Mineral Processing GmbH, Austria Fine Impact Crusher

.jpg)

The selection and design of Crushing equipment Mineral

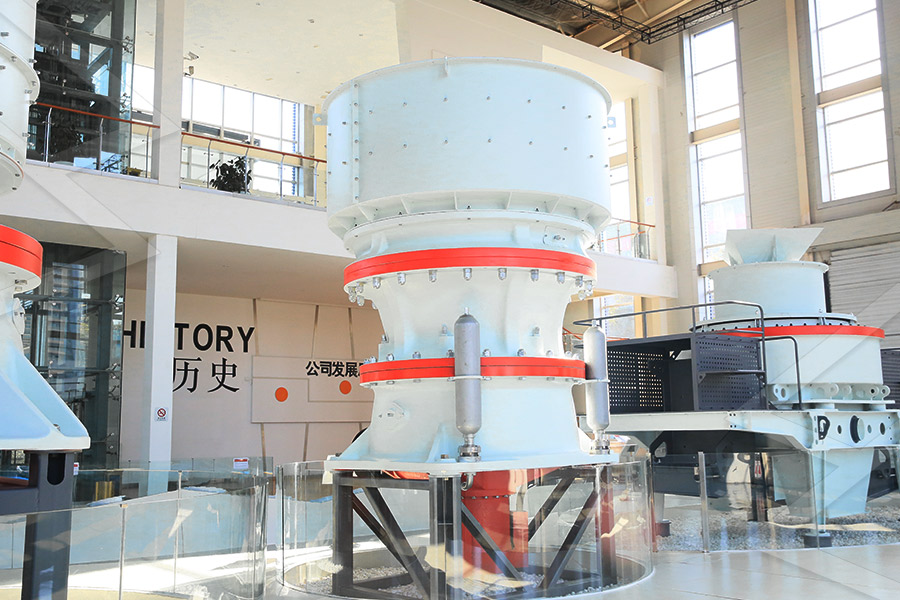

2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact Shanbao PFSeries Impact Crushers include secondary and tertiary Impact Plate which can handle materials less than 100800mm in length; it is suitable to crush medium hard material with compressive resistance of 350MPa The discharge materials from the impact crusher are small and have fine granularity of cubic shapeCrushers and Screens – PT Marton Tekindo Abadi2018年7月20日 The sand production ratio (Sp) is defined as the masspercentage of fragments which are not larger than 475 mm in size The value of Sp is expressed as: [5] where mi is the mass of fragments no larger than 475 mm in size and m0 is the total mass of the fragments The energy consumption per unit sand product (Es) is expressed as:[6]Particle size distribution and energy consumption during 2021年3月1日 The frequency distribution histograms of the factor K for 100 mm long corroded wire elements are shown in Fig 18 The minimum Gumbel distribution is used herein to model the distribution of the factor K, and the KolmogorovSmirnov (KS) test method is also adopted to examine the frequency distribution of the stress impact factor KProbability distribution model of stress impact factor for

.jpg)

Numerical Simulation of a Single and DoubleRotor Impact Crusher

2022年1月25日 A number of experiments were conducted on a laboratory batch impact crusher to investigate the effects of particle size and impeller speed on grinding rate and product size distribution2024年10月18日 Impact crushers: Impact crushers utilize the impact principle They are versatile and can be used in any stage of the crushing process Available in two subtypes: horizontal shaft impact (HSI) crushers and vertical Metso Crushers Screens in OK TX2023年2月23日 The impact crusher working principle involves a highspeed rotor that rotates around a horizontal axis The rotor is equipped with a series of hammers that strike the material as it enters the crushing chamber The material is then shattered against the hardened steel plates that line the crushing chamber The shattered material falls through Understanding the Impact Crusher Working Principle for2017年9月1日 Nikolov (2002) considered the dynamic behavior of impact breakage and proposed new breakage and classification functions that were meant to be specific for impact crushers, which were, in turn, coupled to the Whiten crusher model for the calculation of the product size distribution These functions were related to important operational Mathematical modeling of a vertical shaft impact crusher using

.jpg)

Buyer’s Guide: Crushers Equipment Contracting

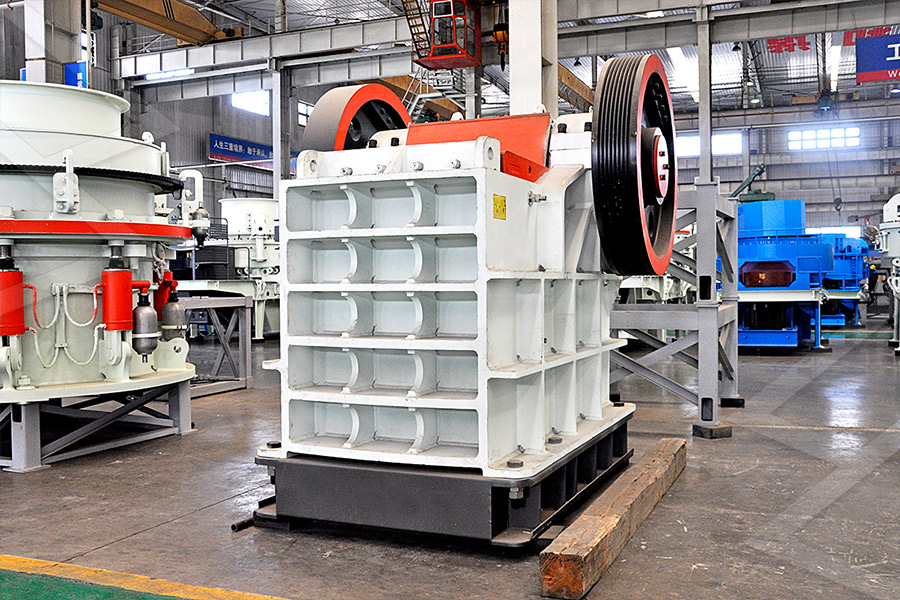

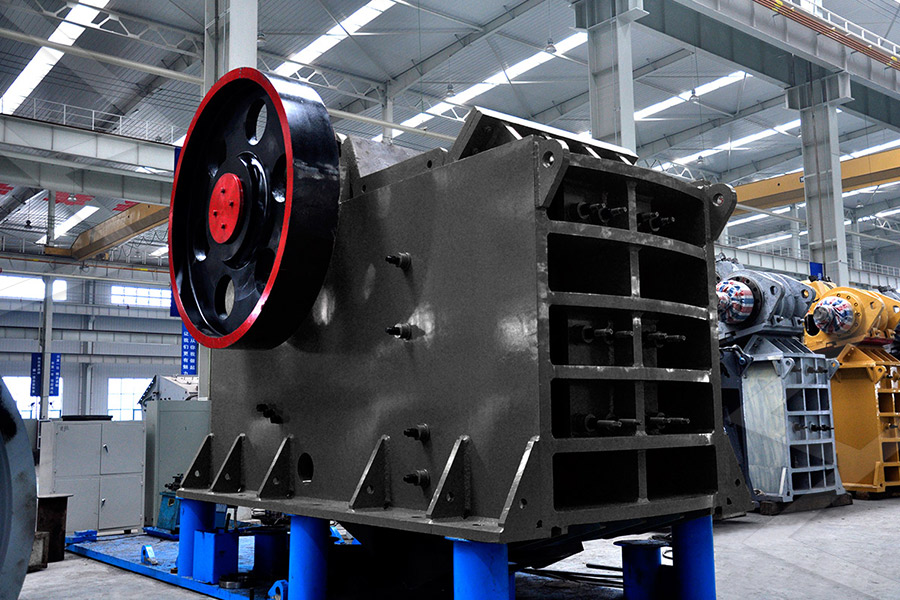

Impact Crushers An impact crusher (also called a hammer crusher) is quite versatile It can be used as a primary, secondary, or tertiary crusher Impact plates and beaters – or hammers – are used to break down the material The material is fed through the upper part of the crusher then hit by hammers Next, the pieces are thrown toward the 2024年2月7日 Particles in the vertical shaft impact crusher absorb and dissipate collision energy in the impact breakage The distribution of the collision energy determines the breakage rate of materials and breakage energy consumption of the entire system In this paper, Collision Energy Analysis within the Vertical Shaft Impact 2022年8月29日 Distributor plate Rotor tip Tip/cavity wear plate Trail Plate Rotor weidment Feed eye ring Upper wear plate The Kinglink KLSeries Vertical Shaft Impact Crusher can crushed metallurgical slag, which achieve slag recycling 3 6 Model MaxFeeding Rotation Speed (r/min) Power Capacity WeightVertical Shaft Impact Crusher machinerylinefoImpact crushers are versatile crushing machines that can be used in any stage of the crushing process However, the features and capabilities of different impact crusher types vary considerably Impact crushers are traditionally classified to two main types: horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushersCrushers All crusher types for your reduction needs Metso

How Impact Crushers Work: A Comprehensive Guide AGICO

2023年3月11日 One of the significant benefits of using an impact crusher is the ability to produce a uniform product size distribution The highspeed impact force generated by the hammers breaks the material into smaller pieces of nearly the same size, allowing for easier control of the final product size Choosing the right impact crusher depends on Impact hammer crusher is a costeffective solution for processing abrasive and moderately sticky raw materials in one stage It is our latest generation of impact crusher with the international advancedlevel quality, which is designed and produced based on absorbing the latest technology of impact crusher in the worldimpact hammer crusher distributor in Nigeria2024年9月3日 Note: The impact score or impact index shown here is equivalent to the average number of times documents published in a journal/conference in the past two years have been cited in the current year (ie, Cites / Doc (2 years)) It is based on Scopus data and can be a little higher or different compared to the impact factor (IF) produced by Journal Citation ReportDiversity and Distributions Impact Factor (IF), Overall 2023年11月1日 Feed particle size distribution has a substantial impact on DRC mass throughput Already a minor number of scattered oversized lumps, not nipped immediately by the DRC rolls, impact the crusher throughput substantially Abstract In the literature, it is also referred to as the “loosening factor” (Höffl, 1985) or “solids contentNew insights into double roll crushing ScienceDirect

.jpg)

Collision Energy Analysis within the Vertical Shaft Impact Crusher

2024年2月7日 Particles in the vertical shaft impact crusher absorb and dissipate collision energy in the impact breakage The distribution of the collision energy determines the breakage rate of materials and breakage energy consumption of the entire system In this paper, the gas–solid coupling method is used to explore the regional distribution of collision energy, collision As a result, they switched to an impact crusher specifically designed for handling harder materials The change brought about a significant increase in productivity! Another case study involved a construction company working on a road project They initially opted for an impact crusher due to its reputation for high production parison of cone crusher and impact crusher productivity crusher, in which the particles are broken during impact Particle fragmentation characterization aims to quantify the size distribution of the product and establish theParticle size distribution and energy consumption during Engineered to produce highquality, wellshaped particles and fine aggregates (eg sand), the Trio® vertical shaft impact crusher (or "vertical shaft impactor"), uses innovative technology to deliver outstanding performance in tertiary and quaternary crushing applications This specialised, high performance vertical shaft impact crusher is designed to deliver flexibility through its Trio® TV Series Vertical Shaft Impact (VSI) Crushers Weir

Impact Crusher Working Principle 911Metallurgist

2015年6月23日 The pendulum product distribution is a breakage function and can be used in models of the process to predict crusher product distributions for different operating conditions As an example of this approach, Whiten’s model of the cone crusher, Fig (9), has been used to simulate the situation given in Fig (4)2024年7月26日 This impact comes primarily from a high speed rotating rotor, mounted horizontally in the crusher and fitted with replaceable hammers • The hammers are manufactured from a high wearing material that can also withstand the high energy impact forces within the crusher • The rotor design is an important factor in the efficiency of the crusherHSI Crushers 911 MetallurgistDownload scientific diagram Distribution of impact (crushing) work index for selected materials measured using the Bond pendulum (symbols: experimental data; lines: lognormal fit) from Distribution of impact (crushing) work index for selected HAZEMAG impact crushers can handle individual lumps of feed material up to 8 tons in weight and 3 m3 (100 cuft) in volume, effecting the comminution process in a single pass at capacities of over 2200 tons/hour Even feed material with a high moisture content up to 15% H2O can be processed without any problems by the provision of indirect IMPACT CRUSHERS HAZEMAG

Control oriented modeling of flow and size distribution in

2014年2月1日 A dynamic cone crusher model that describes the output size distribution (size reduction), and the flow was presented in this work Simulations have showed that the steadystate model behavior is qualitatively consistent with measured crusher behavior, as reported in eg ( Lee and Evertsson, 2011 ), in terms of response to changing the The impact crusher range from Powerscreen is ideal for shaping applications, making chips, sand, concrete manufacture, and glass recycling Trakpactor 260SR features a postscreen system and recirculating conveyor that can Impact Crusher Powerscreen Impact Crushers 2021年8月15日 Higher powder factor also decreases the SSE of the whole circuit The rock fragmentation parameter, Rock Quality Designation (RQD), mainly impacts the coarser end of ROM size distribution; as the primary crusher breaks those coarser particles, no significant RQD effect on the plant throughput and the Size Specific Energy was observedUnderstanding the impact of geotechnical ore properties and blast 2024年4月19日 Impact Crusher: Uses highspeed rotors with attached hammers or blow bars to strike and break material product and the possibility of other screening or classification equipment are largely dependent on the particle size distribution that is required The capital cost of crusher is the most important factor to consider before the Types of Crushers Explained: Everything You Need to Know

.jpg)

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

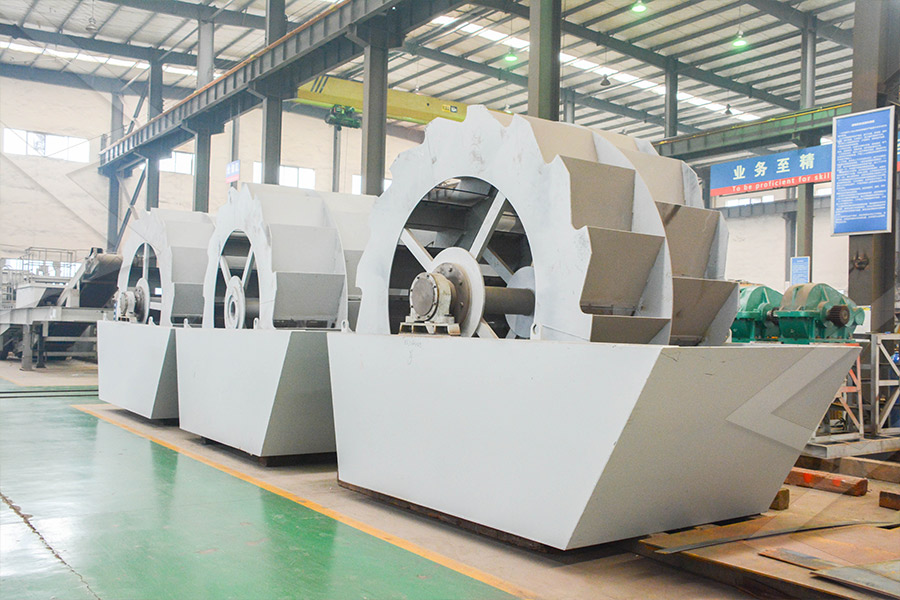

2021年12月3日 The present study investigates the effects of rock crushing circuits on aggregate quality For this purpose, a crushingscreening plant located in Vize (Kırklareli, Turkey) was consideredThe fine impact crusher SMR/CI is mainly used to produce sand which is an excellent additional material for the production of concrete and asphalt This crusher shows a sturdy construction and can easily be adjusted to varying operation conditions thanks to using different rotors Wear is reduced due to the special impact chamber geometry and SBM Mineral Processing GmbH, Austria Fine Impact Crusher2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact The selection and design of Crushing equipment Mineral Shanbao PFSeries Impact Crushers include secondary and tertiary Impact Plate which can handle materials less than 100800mm in length; it is suitable to crush medium hard material with compressive resistance of 350MPa The discharge materials from the impact crusher are small and have fine granularity of cubic shapeCrushers and Screens – PT Marton Tekindo Abadi

Particle size distribution and energy consumption during

2018年7月20日 The sand production ratio (Sp) is defined as the masspercentage of fragments which are not larger than 475 mm in size The value of Sp is expressed as: [5] where mi is the mass of fragments no larger than 475 mm in size and m0 is the total mass of the fragments The energy consumption per unit sand product (Es) is expressed as:[6]