Ball Charge In Ball Mills What Is

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and COThe normal charge of balls is about 5 Mg/m 3 In small mills where very fine grinding is required, pebbles are often used in place of balls In the compound mill, the cylinder is divided into a Ball Mill an overview ScienceDirect Topics2024年10月13日 The ball size distribution in a ball mill refers to the range of ball sizes used in the mill It is typically represented as a cumulative percentage of the total ball charge The Ball size distribution in ball mills: Optimization and impact on 2022年2月10日 The document discusses ball charge management in ball mill systems It addresses the need to top up the ball charge as balls wear down Ball Charge Management PDF Mill (Grinding)

(PDF) Effects of Ball Size Distribution and Mill Speed and

2020年7月2日 In recent research done by AmanNejad and Barani [93] using DEM to investigate the effect of ball size distribution on ball milling, charging the mill speed with 40% small balls 2023年3月24日 grinding results, the MM 500 nano or Planetary Ball Mills should be used (optimized jar geometry) The Mixer Mills are also used for cell disruption of biological cells Guidelines for sample amount and ball charge ContentIn semiautogenous grinding (SAG), the grinding mill inventory, (ie volume of total charge, volume of ball charge, etc) is important in determining the optimum operating condition for SAG mill ball charge determination and its influence on mill 1994年2月1日 The formulation and verification of the discrete element model for the ball charge motion in a ball mill are described in Part I Here, the model is used to simulate the charge Simulation of charge motion in ball mills Part 2: numerical

Numerical simulation of charge motion in ball mills Springer

1993年5月1日 This paper focuses on the use of a numerical tool known as the discrete element method (DEM) to study the motion of ball charge in ball mills DEM is employed to simulate the The charge filling in a ball mill is about 30–45% of the internal volume of the mill, about 40% of this being void space As discussed in Section 722, the reason is the power draw passes through a maximum at about a filling of 45% Given the cost of media it may be economic to operate at the lower end of the filling range, even at the Ball Mill an overview ScienceDirect Topics2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their properties(PDF) Grinding Media in Ball MillsA Review ResearchGateThe raw mill will be operate with a much coarser ball charge than the cement mill mainly because of the bigger slot sizes of the partition wall The transition zone consists of 50 mm and 60 mm balls The basis is a 50 mm ball size for 5% residue on the 4 mm sieve In case bigger grains are bypassing the partition through the center grate even Ball charge optimization INFINITY FOR CEMENT EQUIPMENT

Mill Charge an overview ScienceDirect Topics

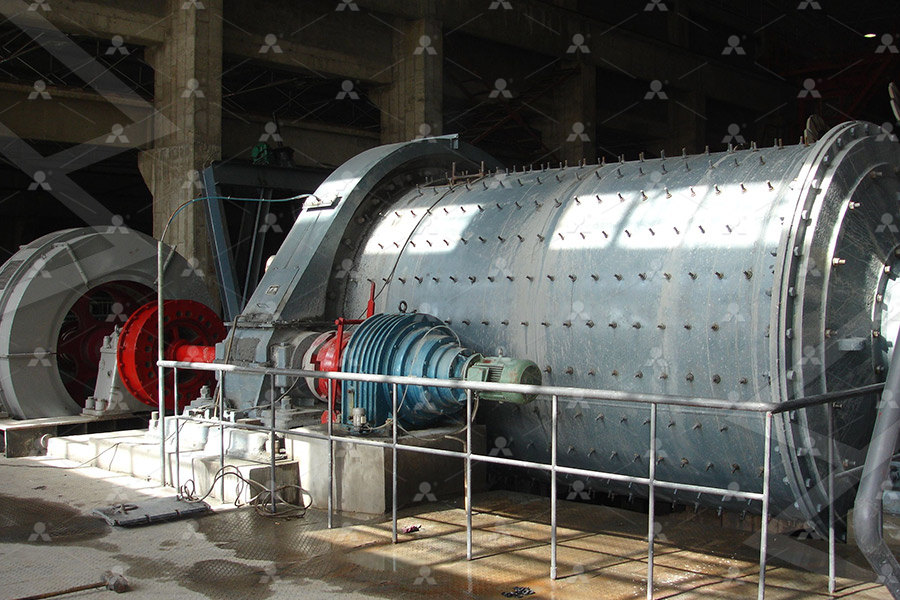

Autogenous and SemiAutogenous Mills In Mineral Processing Design and Operations (Second Edition), 2016 933 M ill Charge Usually, an SAG mill is charged to 30–35% of its interior volume The grinding balls occupy 5–15% of the volume [10]The charge volume can be estimated by measuring the distance between the top level of the charge and the central axis 2017年2月13日 Data on ball charges for BallRod Mills are listed in Table 5 Further information regarding grinding balls is included in Table 6 What is the Steel Charge of a Ball Mill Difference Between a Rod Mill and Ball Mill Rod Mills has a very define and narrow discharge product size range Feeding a Rod Mill finer rocks will greatly impact its Ball Mills 911MetallurgistPelletizing plant of the GolEGohar mining and industrial company consists of a burner, a dry ball mill (62 m × 13 m), and an air separator The ball mill consists of a 2 mlong drying and an 11 ExpandSimulation of ball charge motion in ball mills Semantic 2024年10月13日 1 Ball Size Distribution in Ball Mills: The ball size distribution in a ball mill refers to the range of ball sizes used in the mill It is typically represented as a cumulative percentage of the total ball charge The optimal ball size distribution ensures maximum contact area between the balls, leading to efficient grindingBall size distribution in ball mills: Optimization and impact on

.jpg)

Ball charges calculators thecementgrindingoffice

2018年7月24日 Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of 1995年1月1日 This paper focuses on the use of a numerical tool known as the discrete element method (DEM) to study the motion of ball charge in ball mills DEM is employed to simulate the motion of individual (PDF) Ball Charge Dynamics in a Planetary Mill ResearchGate2024年9月24日 The first order kinetics of grinding occurred for all ball charges and for all samples As the ball charges and narrow, the size fractions of the samples have different masses In this research, the grinding efficiency has also been observed through the specific mill throughput per ground product, per unit mass of the ball charge Q sTHE OPTIMAL BALL DIAMETER IN A MILL 911 2023年6月28日 ball charging grinding media handling automatic safe sorting and handling of grinding media in the range 27mm to 150mm diameter 2 from delivery to mills ball storage winner innovation excellence award 2012 winner cy o'connor award for excellence in engineering technology 2012 transminauBALL CHARGING GRINDING MEDIA HANDLING

Optimization of the makeup ball charge in a grinding mill

DOI: 101016/03017516(92)900769 Corpus ID: ; Optimization of the makeup ball charge in a grinding mill @article{Concha1992OptimizationOT, title={Optimization of the makeup ball charge in a grinding mill}, author={Fernando Concha and L Magne and Leonard G Austin}, journal={International Journal of Mineral Processing}, year={1992}, volume={34}, pages={231 2024年7月12日 Unlock ball mill technology Discover how these versatile machines are used for industries for grinding and blending materials efficiently The agitation process in vibratory mills involves the charge of powder and milling tools being agitated in three perpendicular directions at extremely high speeds, up to 1200 rpm This intense motion What Is a Ball Mill and How Does It Work? (Overview 2024)2024年5月27日 Ball mills are widely used in the beneficiation process for various ores and minerals, including gold, copper, iron, and zinc The TITAN design enables you to run a full process load with a 40% ball charge at 80% of the critical speed, achieving maximum grinding power for every shell size This design ensures that the mills operate at peak Ball Mills in the Mineral Processing Industry MechProTech2020年7月2日 When the mill charge contained monosized balls, the ball flow regime inside the mill transited to the cataracting and impact breakage was the main breakage mechanism Increasing the fraction of (PDF) Effects of Ball Size Distribution and Mill Speed and

.jpg)

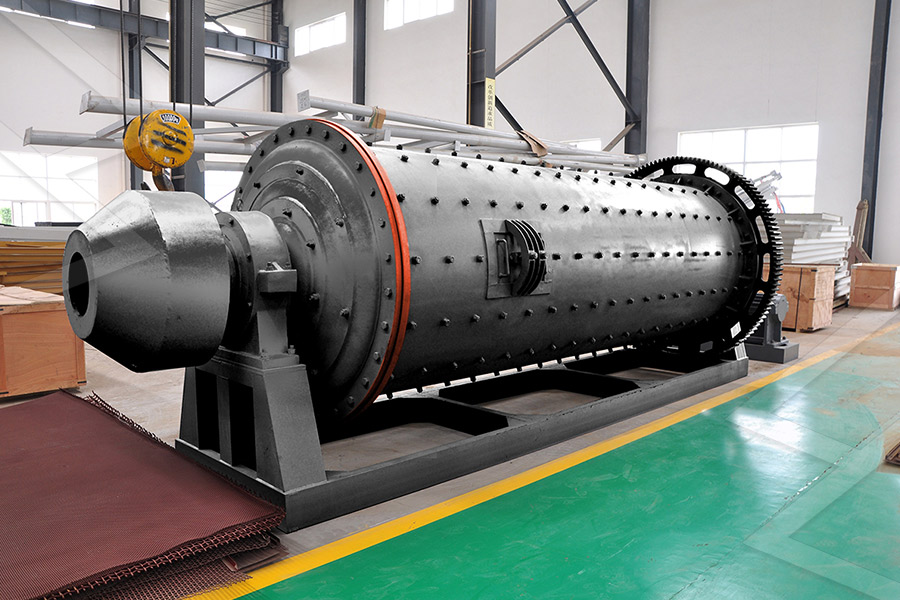

Ball Mill (Ball Mills Explained) saVRee saVRee

Ball Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are employed in the comminution stage as grinding machines (size reduction)The purpose of grinders in the mining industry is to reduce 2022年2月10日 Ball Charge Management Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses ball charge management in ball mill systems It addresses the need to top up the ball charge as balls wear down over time to maintain grinding efficiency and production levelsBall Charge Management PDF Mill (Grinding) NatureBulk Handling Technologies can assist with the design and supply of a custom ball charging system, incorporating a ball receival hopper, feeder and elevating conveyor Feed rate control can be achieved, with mass flow rate measurement if required, with batch or continous systems able to feed varying size balls at rates anywhere from 10 kg/hr to Ball Mills and Ball Charging Bulk Handling TechnologiesBall mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities Understanding their working principle, different types, parts, applications, advantages, and recent developments helps to appreciate their significance and wideranging applications in industries such as cement Ball Mill Grinding Machines: Working Principle, Types, Parts

.jpg)

17 Signs of Problems with Ball Mills: Quickly

2023年2月15日 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to 2021年5月8日 Mill Speed = 75% Nc Ball charge level = 32% v/v Pulp density = 75% w/w Circulating load = 300% Discharge trunnion diameter = 13 m Motor Power draw = 47 MW Discharge trunnion diameter = 085 m Ball charge level = 35% v/v Motor Power draw = 47 MW Ausenco’s Ausgrind Expert Modelling Dia18 x EGL 31 ft : 5500 kW , 750 t/h Higher ball charge Rethinking Grinding Efficiency in Ball Mills RELO 2018年12月18日 Mill ball charging systems have undergone little change during the past two decades Most operations utilize a locomotive/ball car combination to load and haul charges from the ball storage bin to the mill charging boxes or, alternatively, transport charges to the charging boxes by means of a ball bucket handled by bridge crane Ball Mill Charging System 911MetallurgistThe starting point for ball mill media and solids charging generally starts as follows: 50% media charge; Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or decrease the free space) 50% x 26% = 13% free space;Ball Mill Loading Dry Milling Paul O Abbe

.jpg)

Computation of charging media for a double compartment cement ball mill

2024年1月26日 Grinding media is mostly prepared from high chrome steel Ball mills are efficiently utilized for final grinding of clinker It grounds the raw mix (clinker) into fine powder Ball mills are available of different sizes and capacities Ball mill may be of two compartment or three compartments The schematic view of cement ball mill is shown in To understand and describe the behavior of charge dynamics in mills, a series of dry and wet grinding tests were performed on a laboratoryscale ball mill The comparisons between experimental results and grinding media trajectory simulations were addressed Results show that the grinding media trajectory simulations exhibit a good agreement with the experimental Experimental study of charge dynamics in a laboratoryscale ball mill2018年3月20日 It has been used to simulate a 0306m diameter by 0612m long laboratory ball mill with 20% ball filling Steel balls of 19mm diameter were used in the DEM simulation of ball trajectories The mill shell is rotating counterclockwise at 73% critical speed The volume of slurry is 27 times the volume of the void in the ball charge at restPorous Structure of Ball Charge in Grinding Mills1994年2月1日 The friction between the ball charge and the mill shell can increase the power draft The center of the ball mass shifts in distance as much as 4% of the mill diameter during a complete rotation Finally, the distribution of collision energy and the spatial locations of high and lowenergy collisions are shown While many of the simulated Simulation of charge motion in ball mills Part 2: numerical

.jpg)

Ball Mill an overview ScienceDirect Topics

The charge filling in a ball mill is about 30–45% of the internal volume of the mill, about 40% of this being void space As discussed in Section 722, the reason is the power draw passes through a maximum at about a filling of 45% Given the cost of media it may be economic to operate at the lower end of the filling range, even at the 2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their properties(PDF) Grinding Media in Ball MillsA Review ResearchGateThe raw mill will be operate with a much coarser ball charge than the cement mill mainly because of the bigger slot sizes of the partition wall The transition zone consists of 50 mm and 60 mm balls The basis is a 50 mm ball size for 5% residue on the 4 mm sieve In case bigger grains are bypassing the partition through the center grate even Ball charge optimization INFINITY FOR CEMENT EQUIPMENTAutogenous and SemiAutogenous Mills In Mineral Processing Design and Operations (Second Edition), 2016 933 M ill Charge Usually, an SAG mill is charged to 30–35% of its interior volume The grinding balls occupy 5–15% of the volume [10]The charge volume can be estimated by measuring the distance between the top level of the charge and the central axis Mill Charge an overview ScienceDirect Topics

Ball Mills 911Metallurgist

2017年2月13日 Data on ball charges for BallRod Mills are listed in Table 5 Further information regarding grinding balls is included in Table 6 What is the Steel Charge of a Ball Mill Difference Between a Rod Mill and Ball Mill Rod Mills has a very define and narrow discharge product size range Feeding a Rod Mill finer rocks will greatly impact its Pelletizing plant of the GolEGohar mining and industrial company consists of a burner, a dry ball mill (62 m × 13 m), and an air separator The ball mill consists of a 2 mlong drying and an 11 ExpandSimulation of ball charge motion in ball mills Semantic 2024年10月13日 1 Ball Size Distribution in Ball Mills: The ball size distribution in a ball mill refers to the range of ball sizes used in the mill It is typically represented as a cumulative percentage of the total ball charge The optimal ball size distribution ensures maximum contact area between the balls, leading to efficient grindingBall size distribution in ball mills: Optimization and impact on 2018年7月24日 Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of Ball charges calculators thecementgrindingoffice

.jpg)

(PDF) Ball Charge Dynamics in a Planetary Mill ResearchGate

1995年1月1日 This paper focuses on the use of a numerical tool known as the discrete element method (DEM) to study the motion of ball charge in ball mills DEM is employed to simulate the motion of individual 2024年9月24日 The first order kinetics of grinding occurred for all ball charges and for all samples As the ball charges and narrow, the size fractions of the samples have different masses In this research, the grinding efficiency has also been observed through the specific mill throughput per ground product, per unit mass of the ball charge Q sTHE OPTIMAL BALL DIAMETER IN A MILL 911